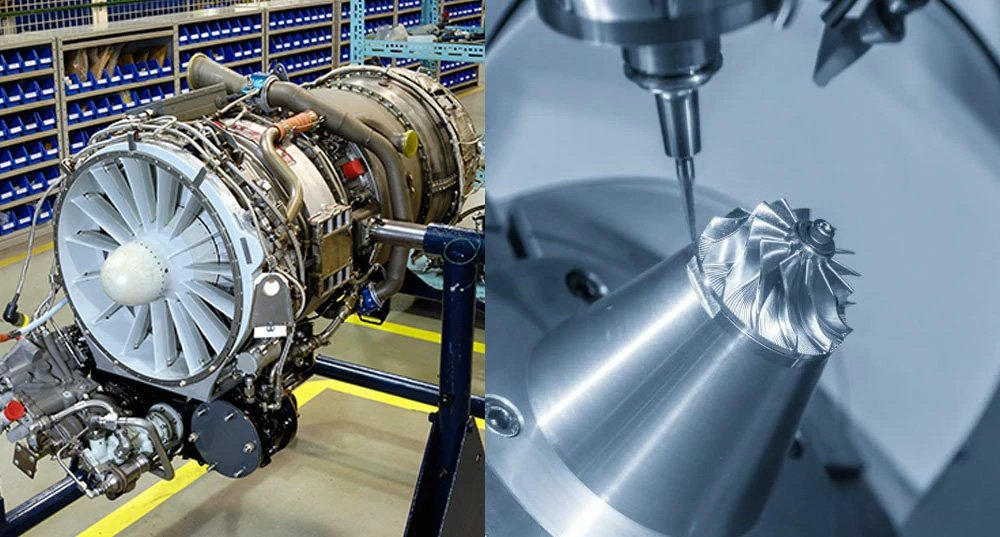

GuanMei PRE is also used in drone parts, metal parts with complex geometry, hydraulic and pneumatic flow parts, and other industries. Our high-precision, high-efficiency, and highly flexible processing industry meets the strict requirements of the aviation industry.

Developing development and production technology has brought great changes to the aerospace field. Lighter materials and fewer design constraints have led to improvements in tools and systems in this field. We have advanced 3-axis, 4-axis, and 5-axis machining equipment to ensure the smooth development of products. Our management system can effectively ensure that the product quality control process meets customer requirements for product accuracy, surface, and performance.

Our engineers will provide manufacturability analysis support according to your product requirements, provide reasonable process analysis, cost reduction recommendations, and increase the competitiveness of the product in the market. We strictly abide by the confidentiality agreement of the project.

Precision machining capabilities

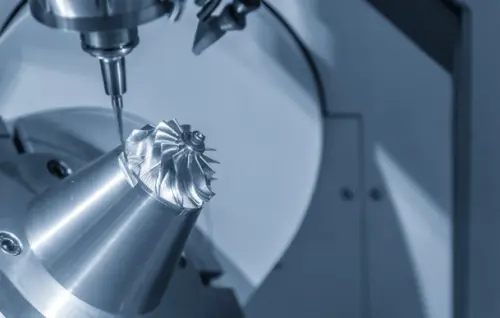

With multi-axis CNC processing capabilities (3-axis, 4-axis, 5-axis), it can stably produce highly complex parts such as aviation structural parts, engine accessories, connectors, etc., maintaining micron-level tolerance control.

Industry Certifications & Standards

We strictly implement international certification standards such as ISO 9001 and IATF 16949, and continuously optimize our quality management system to meet the aerospace industry's stringent requirements for part reliability, traceability, and consistency.

Skilled in processing materials

GM-PRE has extensive experience in aerospace-grade metal processing and is familiar with the characteristics and cutting processes of aerospace materials including titanium alloys (such as Ti-6Al-4V), aluminum alloys (such as 7075, 6061), stainless steel (such as 17-4PH) and high-temperature alloys (such as Inconel).

Surface treatment capabilities

In order to meet the use requirements of aviation parts in high temperature, high pressure and corrosive environments, Guanmei can provide a variety of surface treatment services including anodizing, hard anode, chemical nickel plating, electroplating, passivation, sandblasting, PVD coating, etc.

Fast Prototyping

Guanmei can quickly complete sample delivery within 3 to 7 days, supporting aviation customers in design verification, assembly testing and iterative optimization. At the same time, it has the ability to flexibly switch from small batch high-precision orders to medium and large batch production.

Aerospace Manufacturing Services

CNC Turning is critical for producing high-strength rotational components that withstand extreme aerospace environments. Our precision turning capabilities are trusted for engine & propulsion systems, landing gear & actuation, and auxiliary systems.

CNC Milling delivers complex, lightweight structural components for next-generation aircraft and spacecraft. Key applications include airframe structures, engine components, avionics & instrumentation, etc.

CNC Drilling ensures precision hole patterns for aerospace assembly, fluid systems, and aerodynamic performance. Critical applications include Aircraft Assembly: Fuselage rivet holes, wing spar fastener holes.

Fuel & Hydraulic Systems: High-pressure ports, cooling channel drilling.

Avionics Integration: Sensor mounting holes, laser alignment guides.

Aerospace Parts Applications

CNC Turning Aerospace Parts

Engine & Propulsion Components

- Turbine shafts

- Compressor rotors

- Bearing housings

- Fuel nozzle bodies

Landing Gear & Actuation Systems

- Landing gear pins

- Actuator pistons

- Torque tube assemblies

Auxiliary Systems

- Fluid control valves

- Sensor shafts

- Fastener bushings

CNC Milling Automotive Parts

Airframe Structures

- Wing ribs

- Door hinges

- Bulkhead brackets

- Flap track components

Engine & Turbine Components

- Turbine blades

- Combustion chamber liners

- Fan blade roots

Avionics & Instrumentation

- Radar housing brackets

- Satellite antenna mounts

- Instrument panel frames

CNC Drilling Automotive Parts

Aircraft Skin & Assembly

- Rivet holes for fuselage panels

- Fastener holes for wing spar joints

- Alignment holes for composite layup

Fuel & Fluid Systems

- Fuel line manifold holes

- Cooling channel ports for engines

- High-pressure hydraulic ports

Precision-Guided Components

- Sensor mounting holes

- Laser alignment holes for avionics

- Micro-holes for airflow control

Why Choose GM-PRE

Leverage our company’s advantages to help you better serve your customers

GuanMei PRE are also used in drone parts, metal parts with complex geometry, hydraulic and pneumatic flow parts etc. Our high-precision, high-efficiency and highly flexible processing industry meets the strict requirements of the aviation industry.

Production Capacity

Industry Certifications including IATF16949Provide PPAP

Strict quality control

Provide professional quality inspection report √ Standard Inspection with Formal Report √ CMM Inspection with Formal Report √ Source Material Certification

Instant quote online

The online order page provides different parameters and processes to get a quote quickly

Other Components We Provide