The production of intricate parts has been transformed by CNC (Computer Numerical Control) machining, and of its many methods, 5-axis CNC milling is notable for its unmatched accuracy and flexibility. This article explores the realm of CNC milling businesses, emphasizing 5-axis CNC milling services and the benefits they provide to global industries.

Understanding CNC Milling and Its Evolution

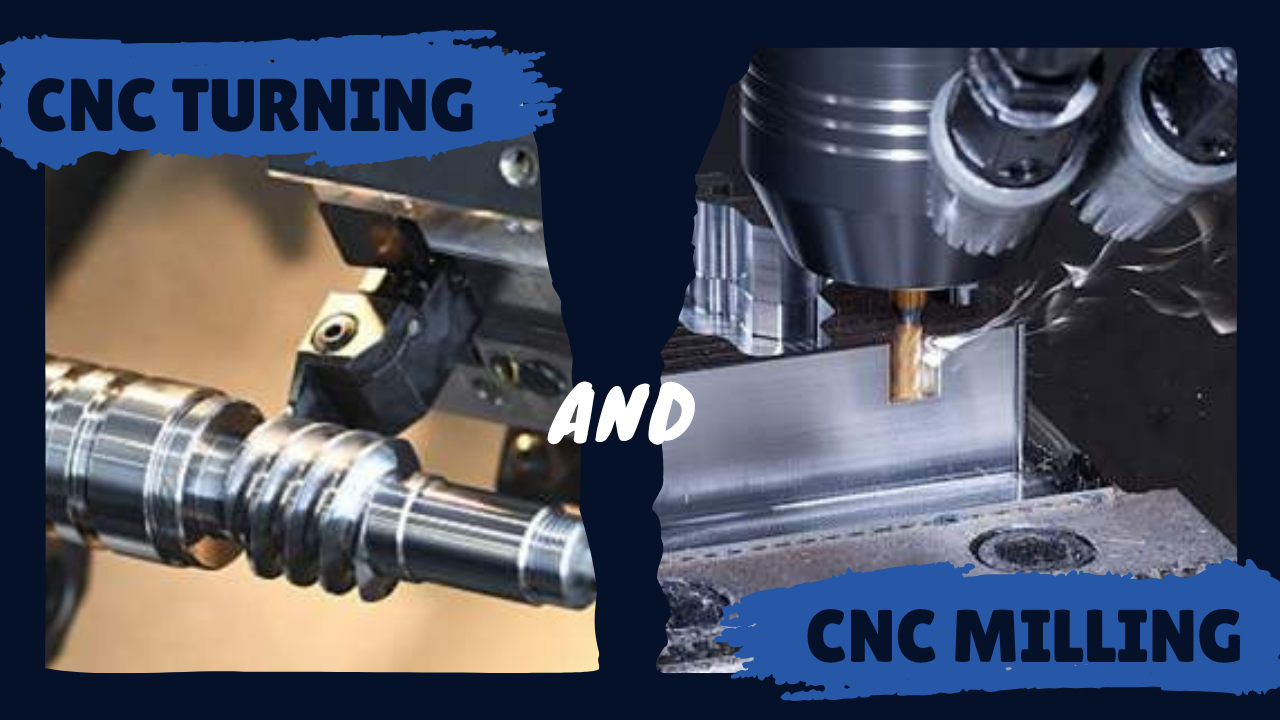

CNC milling is a subtractive manufacturing process that uses computer-controlled rotating tools to remove material from a workpiece, creating custom-designed parts. Traditional 3-axis milling involves movement along three linear axes (X, Y, and Z), but the advent of 5-axis CNC milling has introduced two additional rotational axes, allowing for more complex geometries and intricate designs.

What is 5-Axis CNC Milling?

- Axis CNC milling involves the simultaneous movement of the cutting tool along five different axes, enabling the production of parts with intricate shapes and complex angles. This capability reduces the need for multiple setups, minimizes handling errors, and enhances the overall accuracy of the finished product. The two additional axes can either be the rotation of the table or the spindle, providing a greater range of motion and access to the workpiece.

Advantages of 5-Axis CNC Milling

- Complex Geometries

5-axis CNC milling allows for the machining of intricate designs that would be impossible or highly inefficient with traditional 3-axis machines. This capability is crucial for industries such as aerospace and automotive, where complex contours and shapes are standard.

- Enhanced Accuracy

By reducing the need for multiple setups, 5-axis CNC milling minimizes handling errors, resulting in higher precision and tighter tolerances. This is particularly beneficial for industries requiring high-quality components, such as the medical and aerospace sectors.

- Improved Surface Finish

The ability to maintain an optimal angle between the tool and the surface improves the quality of the surface finish, reducing the need for secondary finishing operations.

- Increased Productivity

5-axis CNC milling combines several machine setups into a single operation, significantly reducing production time and increasing overall efficiency.

- Material Conservation

Efficient tool paths and advanced control minimize material waste, especially when working with expensive materials like titanium or specialized alloys.

6. Reduced Setup Time

Complex parts that would require multiple setups on a 3-axis machine can often be completed in a single setup on a 5-axis machine. This minimizes errors associated with re-fixturing and significantly cuts down on overall production time.

Applications of 5-Axis CNC Milling

Aerospace Components

The aerospace industry relies heavily on 5-axis CNC machining to create parts with complex contours and geometries, such as turbine blades and fuselage sections, which must withstand extreme conditions.

Automotive Parts

From engine mounts to transmission gears, 5-axis CNC milling is essential for producing automotive components that require intricate features and precise tolerances.

Medical Implants

The medical sector benefits from 5-axis CNC milling by producing bespoke implants and surgical tools that require high precision and smooth finishes to match patient anatomy.

Die and Mold Making

Axis CNC milling is ideal for creating complex molds and dies, which are essential for mass-producing other products with detailed features and tight tolerances.

Choosing the Right CNC Milling Company

When selecting a CNC milling company, consider the following factors:

Experience and Expertise: Look for companies with a proven track record in your industry. Experienced providers like RapidDirect and Astro Machine Works offer extensive knowledge and advanced technologies to meet specific manufacturing needs.

Equipment and Capabilities: Ensure the company uses state-of-the-art machinery capable of handling your project requirements. Companies with a diverse range of 5-axis CNC machines can offer greater flexibility and precision.

Quality Assurance: Choose a company with stringent quality control measures and certifications, such as ISO 9001, to ensure your parts meet the highest standards.

Customer Support: Opt for providers that offer engineering support and guidance throughout the manufacturing process to maximize design optimization and output quality.

Use 5-Axis CNC Milling to Welcome the Future of Manufacturing

5-axis A major development in manufacturing technology, CNC milling provides unparalleled accuracy and efficiency for intricate and exacting projects. Working with a trustworthy CNC milling company can revolutionize your production capabilities, regardless of your industry—aerospace, automotive, medical, or any other that needs complex parts. Investing in 5-axis CNC milling services is a smart move for companies trying to remain inventive and competitive. It improves the performance and quality of your components while also cutting production costs and time. Take your manufacturing processes to the next level by investigating the potential of 5-axis CNC milling.

Ready to take your manufacturing to the next level? Contact leading CNC milling companies- GM-PRE to discuss your project requirements and receive instant quotes. Embrace the future of precision machining and unlock new possibilities for your business today.

A Deep Dive into 5-Axis CNC Milling Services