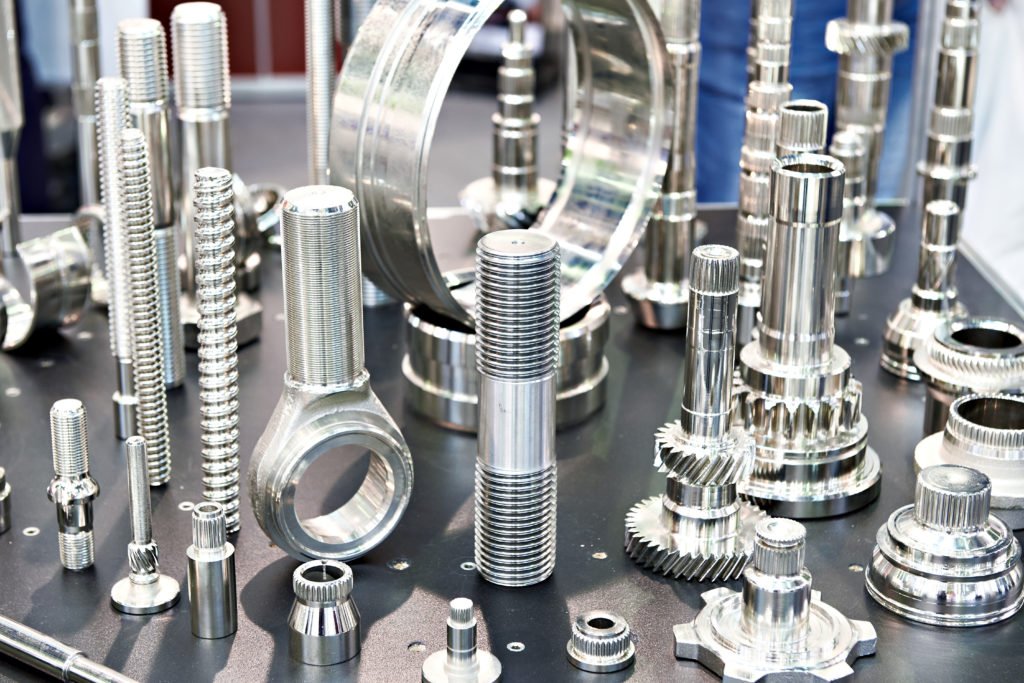

Modern industrial manufacturing has shifted away from single-process machining toward integrated value chains that combine forming, precision machining, and engineered surface treatments in one controlled workflow. For sectors such as aerospace, energy, robotics, and high-performance machinery, this process integration is no longer optional. It is a fundamental requirement for meeting tighter tolerances, complex geometries, and increasingly harsh operating environments.

At the core of these production chains are several high-value process combinations widely used across Europe and North America—such as forged billet to HSM CNC machining, investment casting followed by 5-axis CNC and EDM hole drilling, and closed-die forging supported by CNC hard milling and PVD coating.

Forged Billet → HSM CNC → CMM Validation: Precision from the Start

The manufacturing chain often begins with a forged billet, chosen for its directional grain structure, density, and superior fatigue performance. Once forged, the part moves directly into High-Speed Machining (HSM), which leverages elevated spindle speeds, optimized tooling paths, and lightweight tool assemblies to remove material efficiently while protecting heat-sensitive alloys.

This workflow is ideal for load-bearing components such as turbine brackets, powertrain hubs, steering knuckles, and robotic structural rings. Instead of processing the billet through multiple machine setups, HSM consolidates roughing and semi-finishing into an efficient, highly stable operation. The result is a part that remains structurally aligned with its forged grain, while achieving tighter repeatability and shorter cycle times.

Immediately after machining, CMM validation ensures dimensional accuracy through contact probing or scanning. For B2B customers requiring PPAP, AS9102, First Article Inspection, or GR&R compliance, this step is non-negotiable. It provides traceability, verifies tolerance stack-ups, and confirms that the entire machining chain is under statistical control.

Investment Casting → 5-Axis CNC → EDM Hole Drilling: Precision Finishing for Complex Internal Geometries

For parts requiring intricate cavities or near-net shapes, investment casting remains one of the most efficient upstream processes. However, the casting alone rarely meets the precision needed for aerospace mounts, fuel system components, turbine housings, or medical-grade hardware.

This is where 5-axis CNC machining becomes indispensable. The ability to articulate the cutting tool across five simultaneous axes allows technicians to access complex surfaces, deep pockets, and multi-angle transitions that would be impossible on a 3-axis platform. The synergy between near-net casting and 5-axis finishing minimizes waste, lowers machining time, and preserves the integrity of thin-wall or heat-sensitive sections.

For components requiring micro-flow channels, cooling orifices, or aerospace-grade metering holes, EDM hole drilling completes the workflow. EDM produces extremely small, straight, burr-free holes—even in hardened alloys or nickel-based materials—without distorting surrounding geometry. When combined with 5-axis machining of investment castings, the result is a component with both structural efficiency and precision fluid-control capability.

Closed-Die Forging → CNC Hard Milling → PVD Coating: Strength Meets Surface Engineering

Closed-die forging is the preferred upstream process for applications demanding maximum toughness, impact resistance, and grain-controlled deformation. Industries relying on forged parts include construction machinery, heavy-duty drivetrain systems, pressure-bearing industrial valves, and safety-critical mechanical assemblies.

Because forged materials often reach very high hardness and tensile strength, CNC hard milling is required to machine these components efficiently. Hard milling uses ceramic or coated carbide tooling, optimized chip management, and thermal-stable machine structures to cut materials that may exceed 50–60 HRC. Unlike grinding, hard milling can produce sharp corners, precise edges, and complex geometries without multiple secondary processes.

To enhance corrosion resistance, friction reduction, and wear protection, Physical Vapor Deposition (PVD) coating is frequently integrated into the final stage. PVD layers—such as TiN, TiCN, CrN, or DLC—provide extremely hard, thin, and uniform coatings without altering dimensional tolerances. For forged gears, bearing races, weapon components, hydraulic spools, and high-cycle rotating parts, PVD coatings significantly increase operational life and reduce maintenance costs.

The Value of an Integrated CNC Manufacturing Chain

For B2B customers evaluating suppliers, the capability to execute an entire manufacturing chain under one controlled system offers several critical advantages:

- Dimensional Accuracy Across All Stages

Each process is optimized to support the next, reducing tolerance stack errors. - Shorter Lead Times and Higher Throughput

Consolidated machining and finishing steps reduce logistical delays and inventory handling. - Material-Process Compatibility

Forging, casting, machining, EDM, and coating are matched based on metallurgical requirements—not treated as isolated processes. - Process Documentation and Traceability

CMM validation, SPC data, and full process mapping ensure compliance with aerospace, automotive, and industrial standards. - Lower Total Cost of Ownership for Clients

With fewer subcontractors and reduced rework, clients gain predictable pricing and improved reliability.

This holistic approach reflects a mature engineering mindset: quality is not determined by a single step but by the continuity of the entire production chain.

Conclusion

For industries where performance and reliability are foundational, integrated CNC manufacturing chains provide a clear competitive advantage. Whether starting with a forged billet machined via HSM and verified through CMM, or an investment casting refined with 5-axis CNC and EDM micro-drilling, or a closed-die forging finished through hard milling and PVD coating, the value lies in the synergy of processes.

Suppliers capable of delivering these full-stack workflows offer B2B clients something increasingly rare in today’s global supply landscape: process control, engineering depth, and end-to-end accountability.

Complete Guide to Understanding Pipe Flanges

Advanced CNC Machining for Automotive and Industry