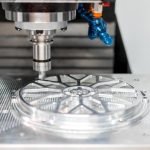

Why Choose GM-PRE For Custom Milling

Our state-of-the-art milling processes enable us to create complex and unique parts to your specifications.

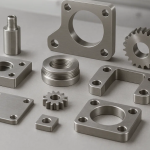

Material Versatility

GM-PRE masters the machining of 40+ materials, from aerospace-grade titanium (Ti-6Al-4V) to medical high-temperature Inconel. Whether you need lightweight aluminum for automotive chassis, biocompatible stainless steel (316L) for surgical tools, our expertise ensures optimal material performance.

Cross-Industry Expertise

With 15+ years of experience, GM-PRE delivers precision-milled components for aerospace, medical, automotive, and other sectors. We can craft titanium engine mounts for supersonic drones and micro heat sinks for AI servers, our engineers understand industry-specific challenges.

Quality Assurance & Certifications

Every GM-PRE part is backed by ISO 9001, ISO 16949 certifications, with full traceability from raw material to final inspection. Our 100% dimensional checks (CMM/3D scanning), X-ray testing for aerospace welds, and RoHS-compliant finishes guarantee reliability.