CNC milling machines are now an important part of modern manufacturing around the world. You can find them in Germany’s industrial hubs, Southeast Asia’s manufacturing areas, and Japan’s tech-driven workshops. Using cutting-edge CNC (Computer Numerical Control) technology, these powerful machines are revolutionizing the manufacturing process globally, from European factories producing precise components for space projects to Asian factories crafting parts for electronics. Let’s look at how CNC milling tools and CNC technology are making manufacturing around the world more innovative, efficient, and competitive.

Why CNC Milling Machines Are Essential in Factories Worldwide

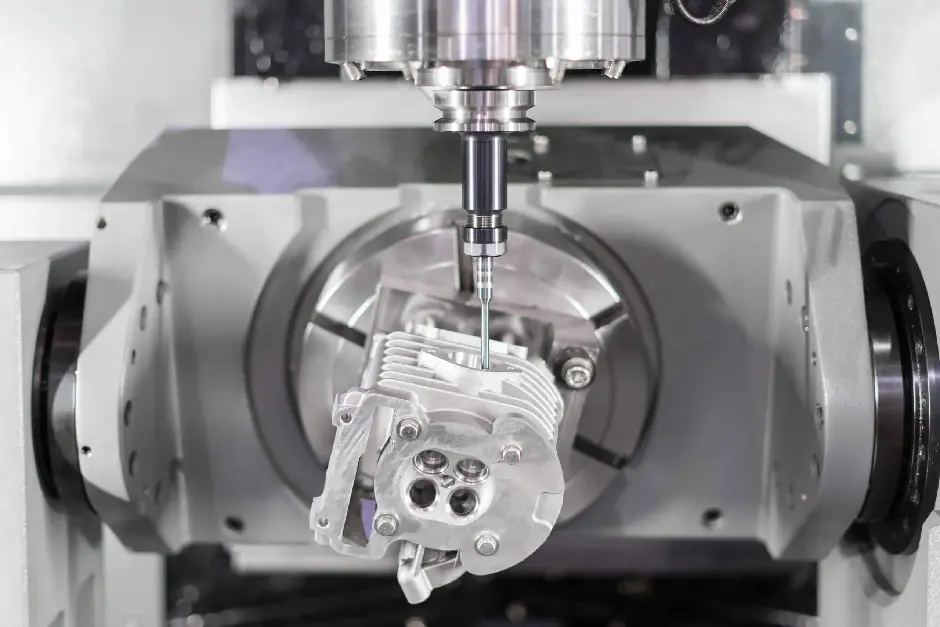

Step into any modern manufacturing facility around the globe, and the steady operation of CNC milling machines is likely to be a prominent feature. Unlike traditional manual milling machines that depend on the skill of operators to manipulate tools, CNC milling machines are governed by computer programs.

With amazing accuracy, they turn digital designs into real parts, often getting tolerances as close as a thousandth of an inch. This level of accuracy changes everything in fields around the world where accuracy is not just a goal but a must.

Because they can do many things, CNC cutting machines are valued by manufacturers all over the world. This text sounds like it was written by a person.

In Europe, these tools cut aluminum for high-speed trains. In India, they shape stainless steel for medical equipment. And in Switzerland, they engrave complicated patterns on titanium for high-end watches. They work with a huge range of materials, from different types of plastic to high-strength alloys. This makes them essential in many fields around the world, including military, healthcare, consumer electronics, and cars.

How CNC Technology is Transforming Global Production Lines

At the core of every CNC milling machine lies CNC technology—the software and hardware that converts 3D models into actionable commands.

In the last ten years, this technology has come a long way, and companies all over the world are using these new developments to stay ahead. One of the most important advances is CNC systems that are linked to the cloud. Imagine a factory in China using a smartphone to keep an eye on the work of a CNC mill in Brazil. Integrating the cloud lets you track data in real time, do forecast maintenance, and fix problems from afar. Then there is CNC code that uses AI.

A group of firms and tech companies is working together to make programs that make the best use of tool paths, reduce waste, and speed up production. Such as in a Mexican plant that makes car parts, an AI system could tell a CNC mill how fast to cut based on how hard the material is. It would help each shift go by faster.

AI technology is important for keeping prices low on the world market because of:

The Global Trend of Heavy Investment in CNC Milling

The statistics are clear: The global CNC machining market is expected to grow at an annual rate of 5.8% through 2030, with many regions outpacing historical averages. So why are manufacturers worldwide investing heavily in CNC milling machines?

First, supply chain resilience.

With CNC mills, local and regional manufacturers can produce high-quality parts quickly, reducing dependence on distant suppliers. A small workshop in Vietnam, for instance, can now manufacture custom components for a local electronics firm faster than importing from other countries, all thanks to the precision of CNC technology.

Second, customization capabilities.

Increasingly, people and businesses around the world are seeking products that are specifically designed for them. This includes everything from custom car parts to specialized industrial machinery. Making one-of-a-kind things or small batches is easy with CNC milling tools. This enables businesses to serve niche markets worldwide. A German-based furniture company, for example, uses CNC mills to create unique wooden components for its high-end furniture lines, setting itself apart from mass-produced alternatives from other countries.

Finally.

Many nations struggle with a shortage of skilled machinists, but CNC technology is assisting in addressing this issue. Modern CNC systems feature user-friendly, intuitive interfaces that shorten the learning curve. Technical schools and vocational training centers across the globe, from South Africa to Australia. Now offer CNC training programs, ensuring a steady supply of workers capable of operating these machines.

The Future of CNC Milling in Global Manufacturing

Looking ahead, CNC milling machines and CNC technology will become even more integral to the global manufacturing landscape. Innovations such as 5-axis CNC milling, which can cut parts from all angles, are already revolutionizing aerospace and defense production worldwide. Leading CNC businesses from Germany, Japan, and the United States are creating machines that are smarter, quicker, and use less energy than ever before.

Additionally, . “Lights-out manufacturing”—factories that run overnight with little human involvement—is made possible by CNC technology. This lowers carbon emissions and energy use. CNC mills are being used by manufacturers worldwide to maximize material use, reduce waste, and support global initiatives to advance environmentally friendly production methods.

In conclusion

These developments are propelling prosperity, generating employment, and guaranteeing that superior, precisely manufactured goods continue to cross international borders, from the factories of Europe to the production facilities of Asia and the workshops of the Americas. Purchasing CNC milling is not a choice; it is a must for every manufacturer hoping to thrive in the global marketplace of the twenty-first century.

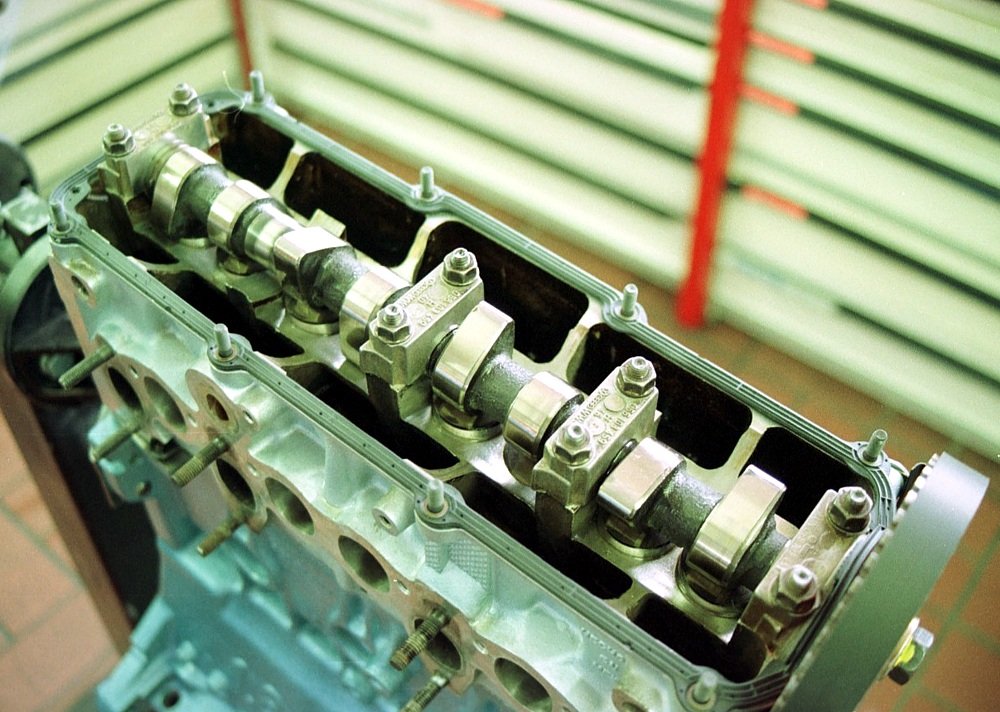

CNC in Camshaft Manufacturing