- Tel: +86-18779223927

- lynn@gmprecnc.com

- NanChang, JiangXi, China

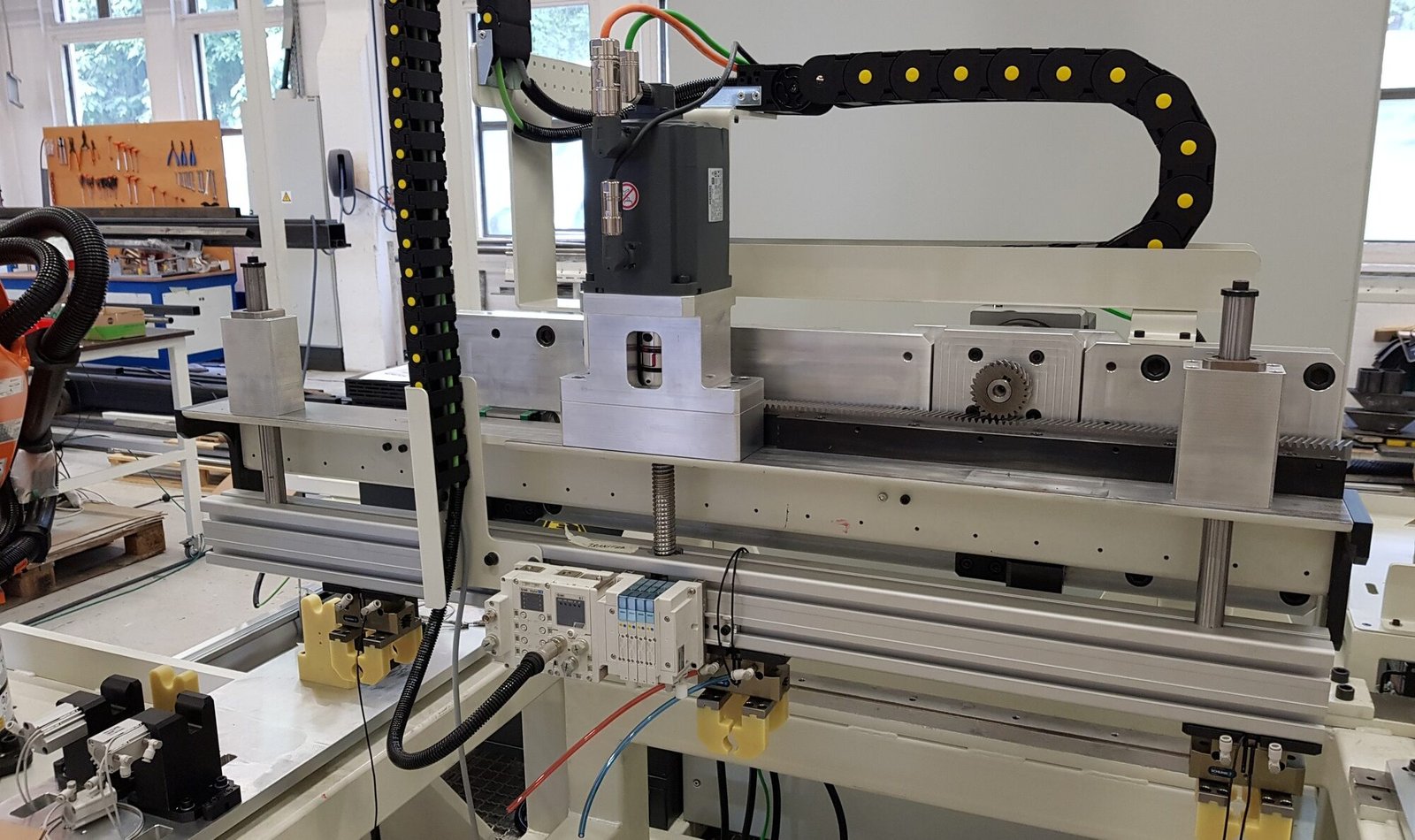

GM-PRE CNC is a professional manufacturer committed to providing high-quality CNC machining parts since 2006, with plant area 15000 square meters, catering to a diverse range of needs.

No matter you require large-scale production or intricate, custom-designed components, we can all satisfy. We are majoring in the field of automotive, medical, aerospace,industry automation,electronics, household etc. We have enough expertise and capabilities to solve your problems.

CNC Turning Parts: We excel in crafting precision turning components, delivering accuracy and consistency in every piece.

CNC Milling Parts: Our state-of-the-art milling processes enable us to create complex and unique parts to your specifications.

CNC Drilling Parts: We provide CNC drilling services for the fabrication of both small and large series of parts of any complexity.

We use various types of drill presses (upright, bench, radial), which allow us to drill holes of both simple and complex patterns up to 7 cm in diameter. The fabrication is possible with metals and alloys (aluminum, steel, copper, and others).

Our online Instant Quoting Engine gives you a CNC machining quote within seconds. Then, we make your machined metal parts and get them to your door in up to 10 days. We inspect the parts and guarantee their quality.

Requesting a quotation for CNC machining is easy: just upload your files with drawings, 3D-models or sketches in any popular format.

Using the latest CNC machines, Guanmei Pre produces highly accurate parts in as fast as 10 days.

Guanmei PRE offers various tolerance options in accordance with lSO 16949 (standard, fine). Our QA department performs strong quality assurance.

Select from a variety of finishes on solid metal parts, built to precise design specifications.

Choose from over 40 metal materials.CNC Machining offers a wide variety of certified materials.

CNC machining can support production of 1-10,000 parts

Guanmei Pre can provide strict certifications and inspection reports

GM-PRE company has demonstrated impressive professionalism and expertise. Their CNC machining services are outstanding, with high product quality and on-time delivery.

I’ve been a mechanical engineer in the automotive parts industry for over a decade, and GM-PRE CNC’s machines have truly raised the bar for us. The precision on their CNC routers is unmatched—we’re seeing tolerances consistently under 0.001 inches, which has cut down our rework by 30%. Their technical team is also incredibly responsive, which makes a huge difference when we’re on tight production deadlines. Highly recommend!

As a production manager at a mid-sized aerospace subcontractor, reliability is everything. GM-PRE CNC’s machining centers have been workhorses for us, and the software integration with our existing systems was seamless. What stands out, though, is their after-sales support. When we had a minor calibration issue last quarter, their technician was solute within 24 hours, no extra charges. It’s clear they care about their clients’ success

Running a small custom metal fabrication shop, we need equipment that’s both precise and user-friendly. GM-PRE CNC delivered on both. Their entry-level milling machine was easy to set up, even for our team with limited CNC experience, and the finish on the parts it produces is consistently smooth. They worked with us on a payment plan that fit our budget. Three years in, it’s still our most reliable piece of equipment.

In medical device manufacturing, there’s zero room for error. GM-PRE CNC’s turning centers are the backbone of our production line for surgical instrument components. The repeatability is spot-on—we’ve run thousands of identical parts, and the variance is negligible

We specialize in prototyping for industrial machinery, so we need CNC machines that can handle quick changeovers and complex geometries. GM-PRE’s 5-axis machining center has been a game-changer. It cuts setup time in half compared to our old equipment, and the accuracy on intricate parts—like the gear housings we prototype—has impressed even our pickiest clients. Their sales rep also took the time to understand our specific needs, recommending the exact model that fit our workflow, not just the most expensive one

GM-PRE CNC machining offers you best services!