Automotive

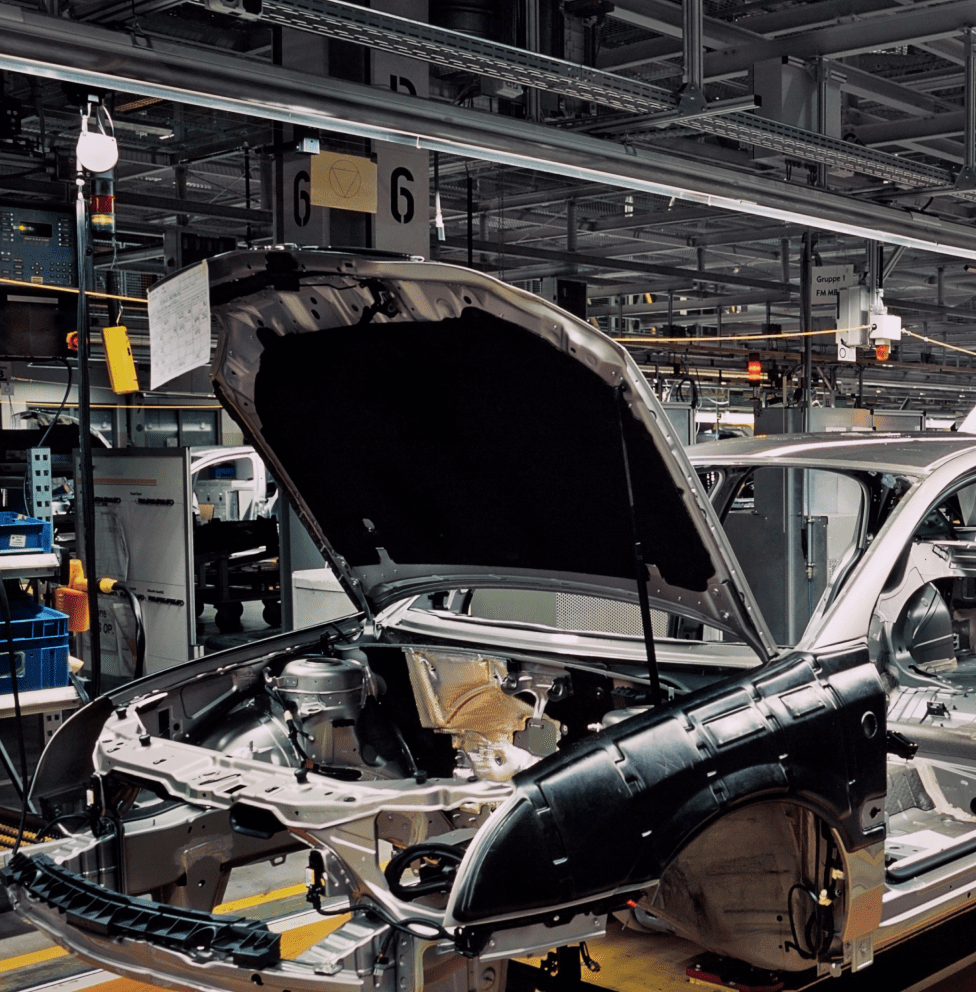

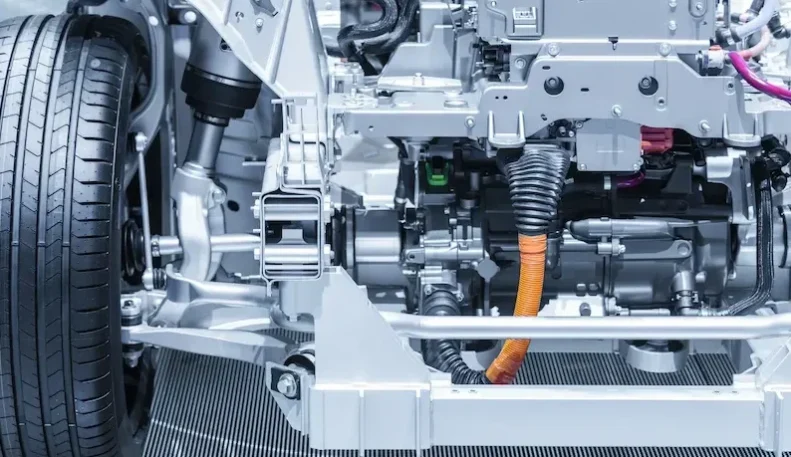

GuanMei PRE has long experience in manufacturing for Automobile suspension systems, air conditioning piping systems, sensor housings, engine parts, etc for world-leading car manufacturers.

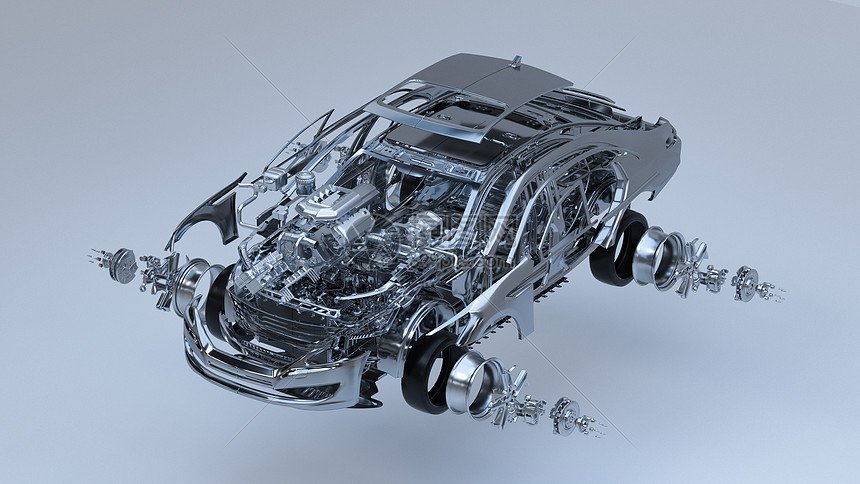

With the production consultation of our professional engineers, you can choose the right production method for your project. In addition, the software we develop and our expert engineers provide feedback to help you adapt your design to your chosen production method and reduce costs.

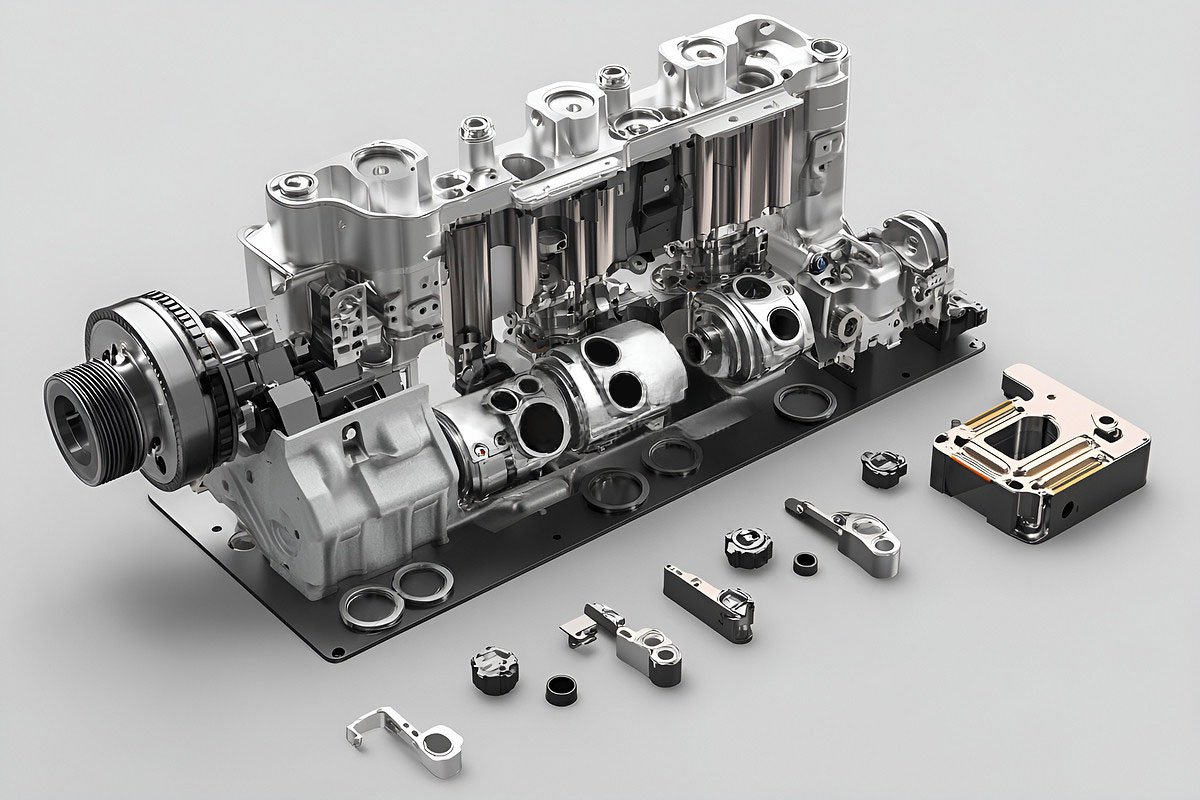

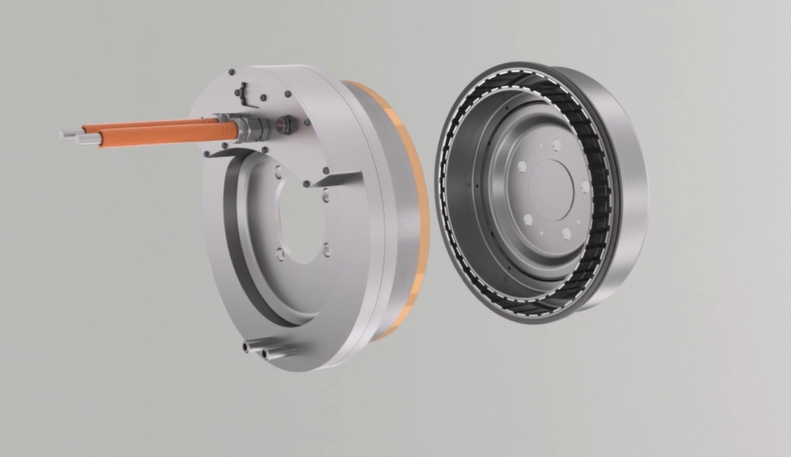

High-Precision Components

Whether it's for engine components, transmission systems, chassis parts, or braking systems, our advanced CNC technologies allow us to manufacture parts with tight tolerances, ensuring superior performance and safety in the final product.

Industry Certifications & Standards

We adhere to international quality standards such as ISO 9001 and IATF 16949, ensuring that every component is manufactured with the highest level of quality control.

Experience with Complex Parts

From complex geometries to intricate details, our skilled engineers are capable of machining even the most demanding automotive components. We’ve successfully produced parts like valves, brackets, bushings, axles, fuel injectors, and more for OEMs (Original Equipment Manufacturers) and Tier 1 suppliers.

Material Expertise

Our team is well-versed in working with various automotive-grade materials, such as stainless steel, aluminum alloys, titanium and carbon steel. Also understand the unique properties required by automotive components: lightweight designs, corrosion resistance and heat resistance. Choosing the appropriate materials ensures long term reliability of each part.

Fast Turnaround & Scalability

Timely delivery of automotive industry production schedules is always a top priority, our streamlined processes and advanced CNC capabilities enable orders to be completed efficiently - whether it is a prototype part or a large-scale production. We are able to scale up production according to your production requirements to ensure timely delivery of production schedules.

Automotive Manufacturing Services

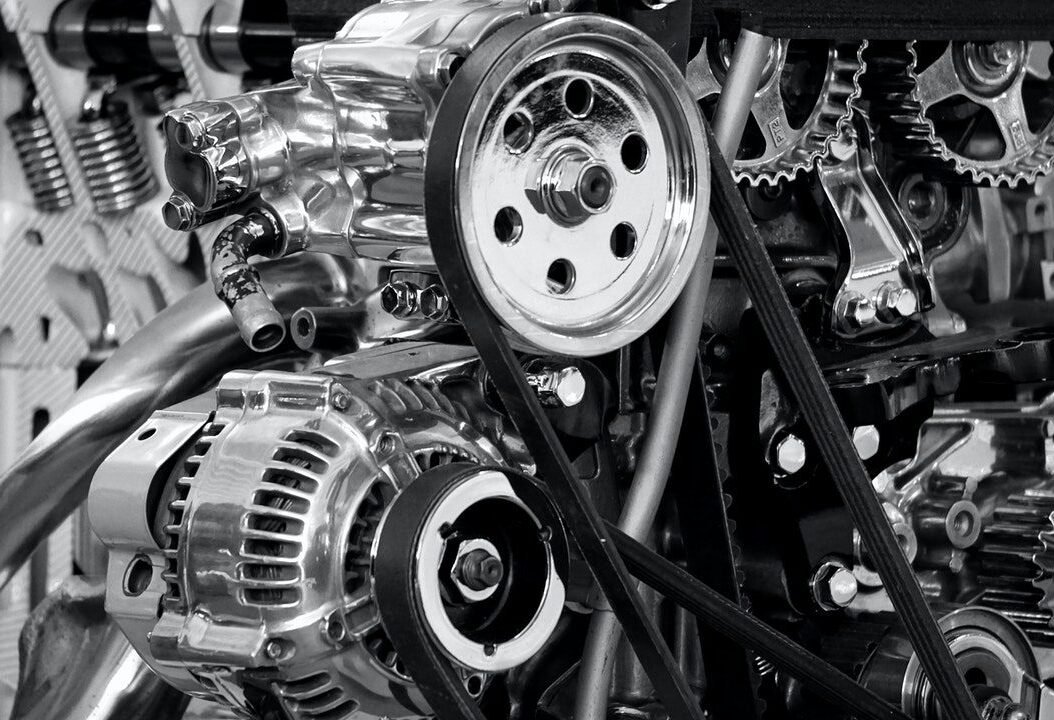

CNC turning is widely used in the manufacturing of automotive parts, mainly for processing rotationally symmetrical parts, such as shafts, wheels, engine parts, etc. It can be used to process various types of aluminum automotive, such as motor housings, pump housings, etc. Through precise turning technology, it can achieve high-precision requirements of automotive parts machining and produce high-quality CNC car parts.

CNC milling is a common way to cut and process automotive parts through computer numerical control technology, which can perform complex cutting and engraving in three-dimensional space. CNC milling is widely used in automobile manufacturing, and capable of machining complex shapes of automotive components, including steering components, Brake components, etc., using advanced automotive CNC machines, to achieve automotive precision machining.

CNC drilling is a technology that uses computer numerical control (CNC) machine tools to perform precision drilling on automotive parts. Guanmei’s CNC drilling service can accurately drill various components in machining car parts, such as motor housings, pump housings, etc., providing a basis for subsequent assembly and other processes, helping automotive vendors and automotive components manufacturers to produce efficiently.

Automotive Parts Applications

CNC Turning Automotive Parts

Engine Components

- Crankshafts / Camshaft

- Pistons / Valve bodies

- Fuel injector nozzles

- Turbocharger shafts

Suspension & Steering

- Tie rods / Ball joints

- Steering knuckles

- Wheel hubs

Transmission Parts

- Gear shafts

- Transmission shafts

- Bushings / Sleeves

Brake System

- Brake caliper pistons

- Brake rotors

- Master cylinder components

Miscellaneous

- Sensor housings

- Exhaust system flanges

CNC Milling Automotive Parts

Engine & Powertrain

- Engine blocks

- Cylinder heads

- Intake manifolds

- Timing chain covers

Transmission & Drivetrain

- Transmission housings

- Differential cases

- Gearbox components

Chassis & Suspension

- Control arms

- Suspension brackets

- Subframe components

Electrical & Sensor Systems

- ECU housings

- Sensor mounting plates

- Connector housings

Custom Components

- Prototype parts

- Lightweight structural parts

CNC Drilling Automotive Parts

High-Precision Drilling Applications

- Engine block coolant passages

- Cylinder head bolt holes

- Brake disc ventilation holes

- Valve guide holes

- Crankshaft oil passage holes

Assembly & Mounting Components

- Bracket mounting holes

- Flange bolt patterns

- Sensor alignment holes

- Connector bolt holes

- Seat bracket holes

Structural & Chassis Components

- Suspension system mounting holes

- Chassis frame holes

- Control arm attachment holes

- Body reinforcements

Exhaust & Fluid Handling Components

- Exhaust manifold mounting holes

- Fuel system attachment holes

- Oil filter mounting holes

- Water pump mounting holes

Why Choose GM-PRE

Leverage our company’s advantages to help you better serve your customers

GuanMei PRE has extensive experience in manufacturing components for automobile suspension systems, air conditioning piping systems, sensor housings, and engine parts for world-leading car manufacturers. We can also provide suitable materials for processing special parts, such as motor housings and pump housings, to meet the diverse needs of automotive component manufacturers.

Production Capacity

Industry Certifications including IATF16949Provide PPAP

Strict quality control

Provide professional quality inspection report √ Standard Inspection with Formal Report √ CMM Inspection with Formal Report √ Source Material Certification

Instant quote online

The online order page provides different parameters and processes to get a quote quickly

Other Components We Provide