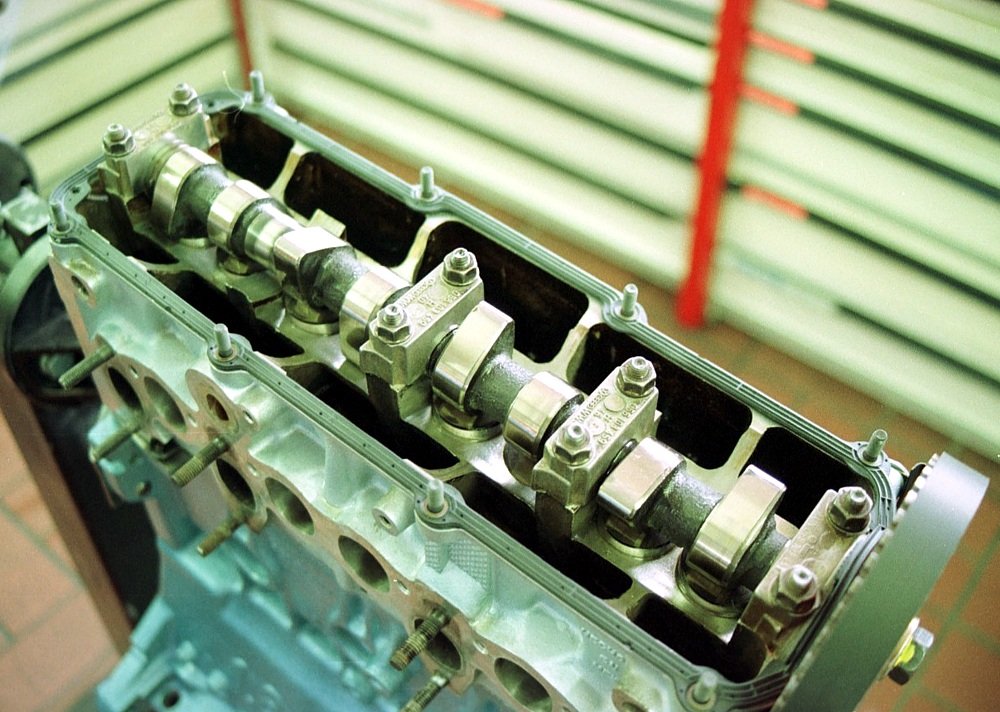

In the subject of automotive engineering, the camshaft is crucial to engine performance. As technology develops, camshaft manufacturing has become much more accurate and productive because to computer numerical control (CNC) machining.This article looks at the difficulties in using CNC technology to produce camshafts and how it has improved engine performance and altered the manufacturing process.. Comprehending the Camshaft An internal combustion engine’s camshaft is an essential part that opens and closes the engine’s valves. It guarantees that exhaust gases leave the combustion chamber effectively and that the proper amount of air and fuel mixture arrive at the appropriate time. Engine performance is strongly impacted by the camshaft’s design, hence manufacturing accuracy is crucial.

The Emergence of CNC in Camshaft Manufacturing

Traditionally, camshaft manufacturing involved manual processes that were time-consuming and prone to errors. The industry saw a change with the introduction of CNC machining. Camshafts are produced with unmatched accuracy, consistency, and efficiency thanks to CNC technology, which uses computer-controlled machinery.

Advantages of CNC Machining in Camshaft Production

- Precision and Accuracy: CNC machines can produce camshafts with extremely tight tolerances, ensuring consistent performance across multiple units. This precision is crucial for high-performance engines where even minor deviations can impact efficiency.

- Efficiency and Speed: CNC machines automate the manufacturing process, significantly reducing production time. This efficiency allows manufacturers to meet high demand without compromising on quality.

- Versatility: CNC machines can easily switch between different camshaft designs and specifications, offering manufacturers the flexibility to produce a wide range of products for various engine types.

- Cost-Effectiveness: While the initial investment in CNC machinery is high, the long-term savings in labor costs and reduced waste make it a cost-effective solution for camshaft production.

Important Procedures for CNC Camshaft Production

The quality and functionality of the finished product are influenced by a number of procedures that are included in CNC machining. The following outlines the crucial steps in the CNC camshaft production process:

- Facing and turning:In the first step, the raw material is turned and faced to form a simple cylindrical shape. Accurate surface finishes and dimensions are achieved with CNC lathes, laying the groundwork for further procedures.

- The process of cam milling:A critical stage in the formation of the camshaft’s lobes is cam milling. The lobes are precisely shaped by CNC milling machines using specialized cutting tools, guaranteeing that they satisfy the engine’s unique valve timing and lift requirements.

- Grinding:A crucial procedure that improves the camshaft’s dimensional precision and surface smoothness is grinding. High-performance servo drive systems are used by CNC grinding machines to achieve consistent surface cutting speed, which produces a precise and smooth finish.

- Grinding in the Journal:By making sure the camshaft’s bearing journals are flawlessly round and smooth, the journal grinding procedure lowers wear and friction while the engine is running. Consistent accuracy is maintained by CNC grinders that have software adjustment for variations in wheel radius.

5.Control of Quality: An essential component of CNC camshaft manufacture is quality control. Modern CNC machines are outfitted with sensors and feedback mechanisms that keep an eye on the operation in real time, guaranteeing that every camshaft satisfies exacting quality requirements.

The Potential of CNC in Camshaft Production Future

Camshaft manufacturing depends on more advancements in CNC technology.With more research and development, we might expect even more precision, efficacy, and customization.Further developments in CNC technology are essential to the future of camshaft manufacture. We may anticipate even more accuracy, effectiveness, and personalization with continued research and development. Further improving the quality and performance of camshafts, the incorporation of AI and machine learning into CNC systems may result in more intelligent and flexible manufacturing procedures. Further improving the quality and performance of camshafts, the incorporation of AI and machine learning into CNC systems may result in more intelligent and flexible manufacturing procedures.

In conclusion

The way camshafts are made has changed because CNC cutting has made them more accurate, efficient, and useful than ever. CNC will become an even more important way to make camshafts that work well with new engines as technology keeps getting better.. People who make things and people who like cars who want to stay ahead in the world of engine performance need to know what CNC technology can do. Companies can be sure they’re making high-quality camshafts that help cars run better and more quickly by using CNC machining.. Whether you work in the auto industry or just like cars, the way CNC technology has changed the production of camshafts shows how engineering and manufacturing are always changing.

CNC in Camshaft Manufacturing

Are You Ready to Start a project?