With the high development speed of aerospace field, It’s our argent needed to apply computer technology to update our products. Modern aircraft—take the Boeing 747, for example—boast over six million components, a complexity that demands cutting-edge technology paired with meticulous craftsmanship.CNC (Computer Numerical Control) machining, a technology that has transformed the manufacturing of aircraft components, is at the core of this engineering marvel.

In this passage, we’ll dive into how CNC machining plays a important role in aviation, why computers are vital to aerospace engineering, and how these technologies are reshaping the future of flight

What is Aerospace CNC Machining?

CNC machining is a manufacturing process where computer-controlled tools craft high-precision parts. In aerospace, its importance is hard to overstate—it lets us create incredibly complex shapes and designs with pinpoint accuracy

The Role of CNC Machining in Aerospace

- Precision and Consistency: Aerospace components require exacting standards due to the high-stakes environment they operate in. CNC machining ensures each part is manufactured with precision, maintaining tight tolerances that are crucial for safety and performance.

- Material Versatility: CNC machines can work with a variety of materials, including lightweight metals like aluminum and titanium, as well as high-performance plastics. This versatility is essential for creating parts that are both strong and light, enhancing fuel efficiency and performance.

- Rapid Prototyping and Production: The ability to quickly transition from design to prototype to production is a significant advantage in aerospace. CNC machining facilitates rapid prototyping, allowing for quick iterations and testing of new designs.

- Complex Geometries: Modern aircraft designs often require complex geometries that traditional manufacturing methods cannot achieve. CNC machining can produce these intricate shapes, making it possible to innovate and improve aircraft designs continually.

Computers’ Significance in Aerospace Engineering

In aerospace engineering, computers are essential to the entire design and manufacturing process, not just CNC machining. They are essential for the following reasons:

Enhancing Design and Simulation

- Computer-Aided Design (CAD): Computers enable engineers to create detailed 3D models of parts and assemblies, allowing for thorough analysis and optimization before manufacturing begins. This reduces the risk of errors and enhances the overall design quality.

- Simulation and Testing: Advanced software allows for the simulation of various scenarios, testing the performance of components under different conditions. This virtual testing saves time and resources while ensuring safety and reliability.

Improving Manufacturing Processes

- Automation and Control: CNC machines are controlled by sophisticated software that automates the manufacturing process, reducing human error and increasing efficiency.

- Quality Assurance: Computers assist in maintaining quality control throughout the production process. They help in monitoring and adjusting parameters to ensure each part meets the required specifications.

Key Insights from Industry Leaders

As highlighted in the top Google search results, companies like Moseys Production Machinists and WayKen emphasize the importance of CNC machining in aerospace. They emphasize how the industry’s need for precise, high-quality products that adhere to stringent regulations is met by this technology. Further propelling innovation in aerospace production is the incorporation of cutting-edge technology like robotics and machine learning, which are improving CNC capabilities.

Overcoming Challenges in Aerospace Machining

While CNC machining offers numerous benefits, it also presents challenges:

- Material Challenges: Working with advanced materials like titanium and high-performance plastics requires specialized knowledge and equipment to avoid issues like tool wear and thermal distortion.

- Complexity and Cost: The initial investment in CNC technology and the training required can be significant. However, the long-term benefits in terms of efficiency and precision often outweigh these costs.

- Regulatory Compliance: Aerospace components must adhere to stringent industry standards. Achieving and maintaining certifications like AS9100 and ISO 9001 is crucial for any manufacturer in this sector.

Wrapping Up: The Future of Aerospace Manufacturing

At the cutting edge of aerospace innovation, CNC machining and computer technology aren’t just tools—they’re the driving force.The aerospace industry’s always changing—and as it does, these technologies are only going to get more important. They’re the ones that’ll make planes safer, more efficient, and more advanced.

For aerospace companies, putting money into CNC tech and skilled workers isn’t just about staying ahead of the competition. It’s something you have to do.

Looking ahead, the teamwork between aerospace engineering and CNC machining is set to take the industry places it’s never been before.

Are You Prepared to Proceed?

Investigating what CNC machining can accomplish is a wise step if your company wishes to increase its aerospace manufacturing capabilities. Staying competitive in this fast-moving market means three key things: keeping up with new skills, investing in top-notch tech, and linking up with industry pros. Wondering how CNC machining services could step up your aerospace projects? Speak with a reliable supplier right now.If you have this tendency to apply this technology to your products,please contact us!

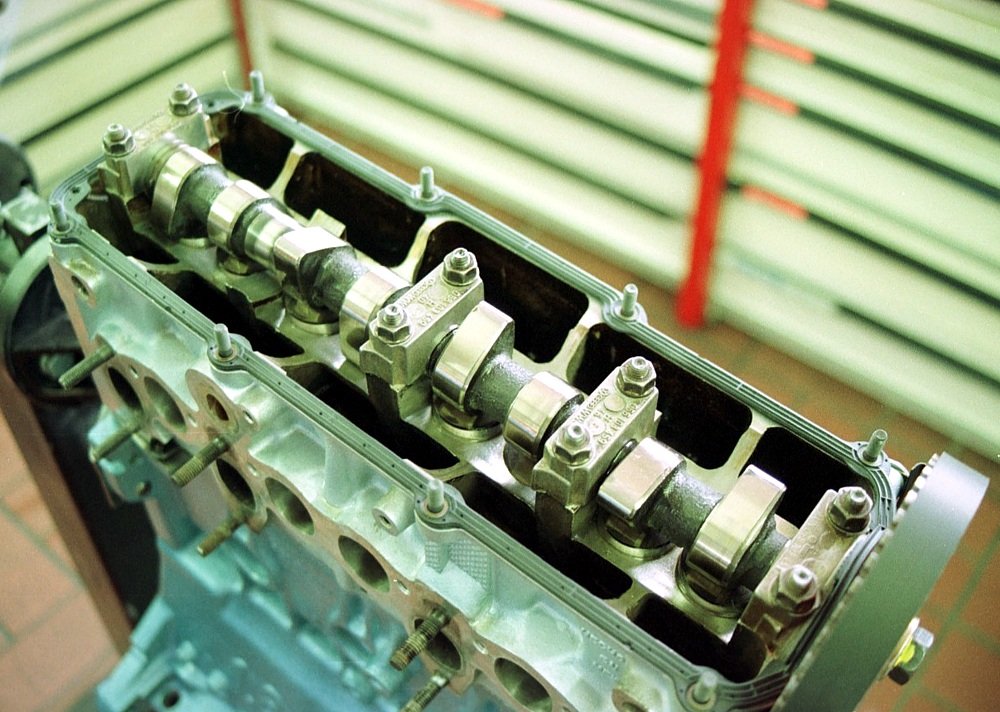

CNC in Camshaft Manufacturing