What is CNC Turning

CNC Turning is a precision machining process that rotates a workpiece on a spindle while a cutting tool removes material to create cylindrical or conical shapes. Controlled by computer numerical code (G-code), it delivers unmatched accuracy (±0.005 mm) for industries like aerospace, medical, and automotive.

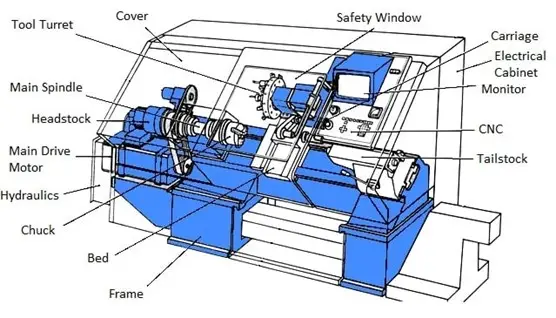

The Basics of CNC Lathes

A CNC lathe consists of core components designed for automated, high-precision operations:

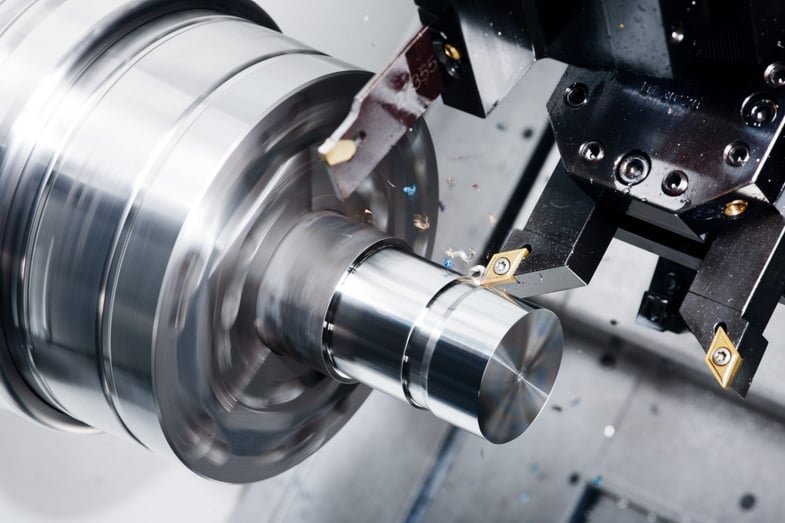

Spindle:

- Rotates the workpiece at 50–5,000 RPM (varies by material and diameter).

- Hydraulic or pneumatic chucks secure parts ranging from 5 mm to 500 mm in diameter.

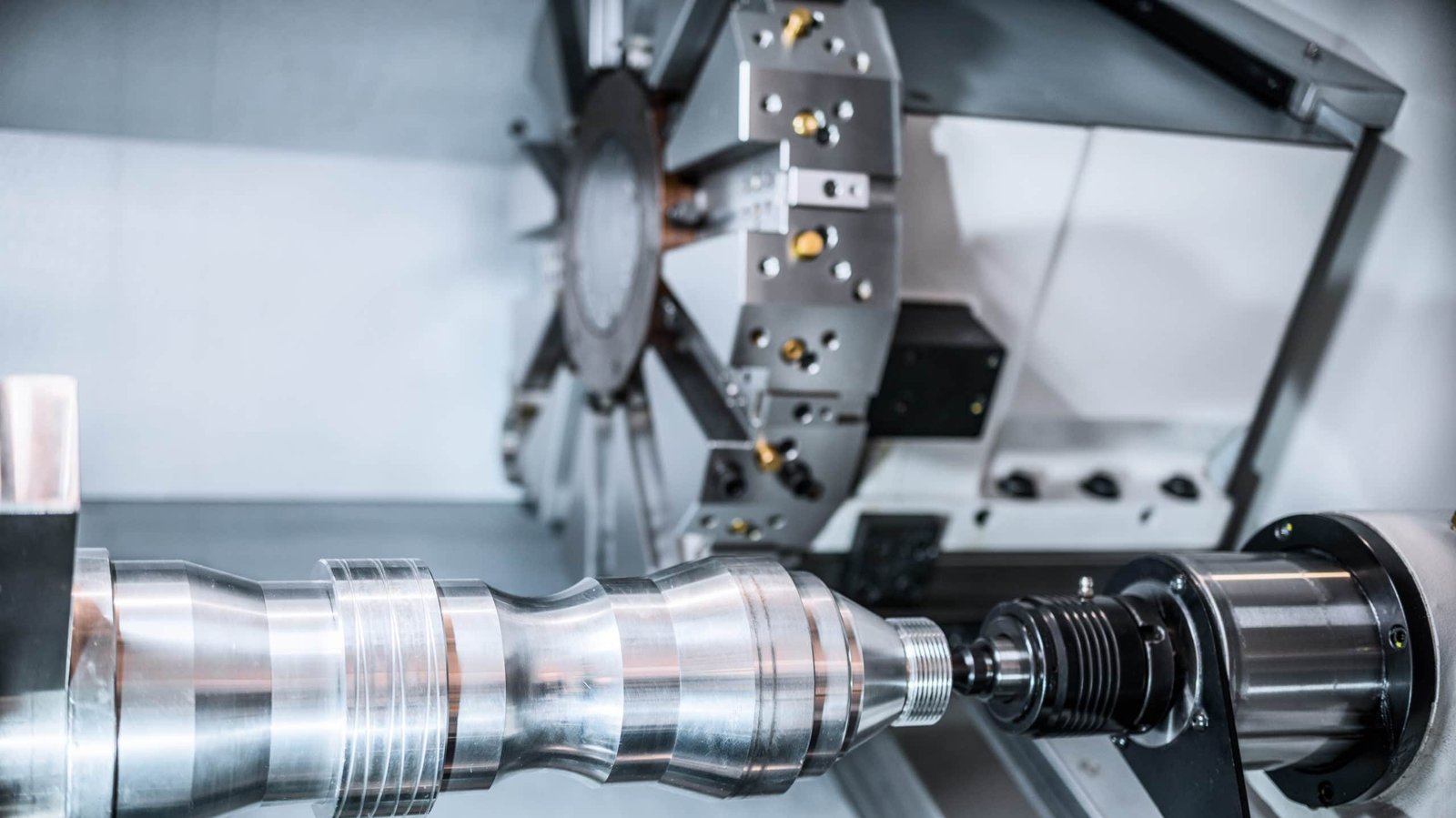

Turret:

- Holds 8–12 cutting tools (turning, drilling, threading) for multi-operation machining.

- Automatic tool changes (ATC) reduce setup time by 70%.

Guideways:

- Linear or box-type guideways ensure rigidity during heavy cutting (e.g., hardened steel).

- Positioning accuracy: ±0.002 mm (with laser calibration).

Control Panel:

- Fanuc, Siemens, or Mitsubishi systems for real-time monitoring and adjustments

How CNC Turning Works

1. CAD/CAM Design:

- Convert 3D models into G-code using software like Mastercam or SolidWorks.

- Optimize toolpaths for minimal material waste (nesting efficiency ≥85%).

2.Workpiece Setup:

- Mount raw material (bar stock, casting) onto the spindle.

- Align using touch probes (accuracy ±0.001 mm).

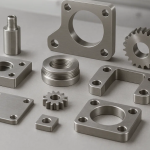

3.Machining Operations:

- Facing: Create flat surfaces (Ra 0.8–3.2 μm).

- Turning: Reduce diameter to target dimensions (±0.01 mm).

- Drilling/Tapping: Add holes or threads (M1–M30).

- Grooving/Parting: Cut slots or separate finished parts.

4.Real-Time Monitoring:

- Sensors detect tool wear, auto-adjust feed rates for consistency.

5.Post-Processing:

- Deburring, anodizing, or passivation for enhanced functionality.