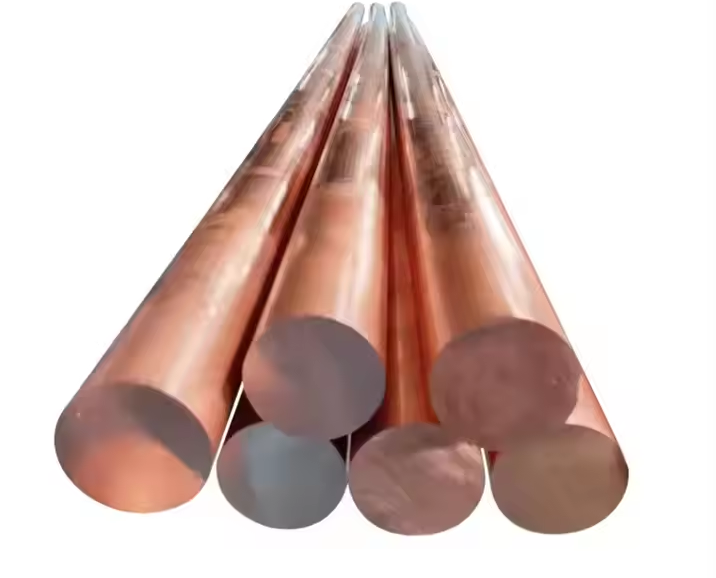

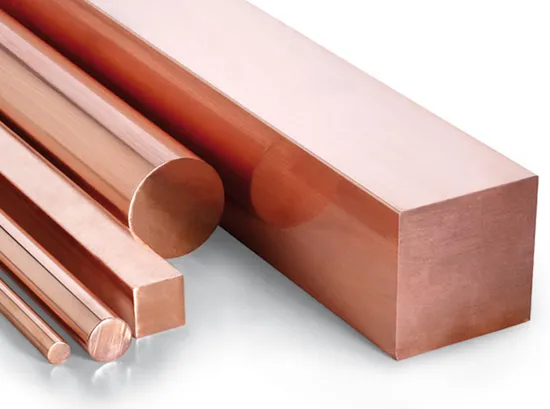

Copper

Copper and its alloys are widely used for their excellent electrical and thermal conductivity, corrosion resistance, and ease of fabrication.

【01】

Alloys

TU0, T1, T2, C10100, C10200, C11000

【02】

US Standard

ASTM B121

ASTM B133

ASTM B152

【03】

EN Standard

DIN EN 1652

【04】

GB Standard

ISO 1338

ISO 1339

Application of Copper Materials

Copper is a reddish-brown metal known for its excellent thermal and electrical conductivity. This makes it one of the most widely used materials in electrical wiring, electronics, and construction. Copper plays a crucial role in CNC machining across a wide range of industries, from electronics and aerospace to architecture and jewelry.

Copper TU0

Surface Treament

Electroplating (tin, nickel),

polishing,

lacquering

Features

Purity: Very high-purity copper (minimum 99.90% Cu).

High electrical and thermal conductivity.

Mechanical Properties: Good strength and ductility, but not as high as other copper alloys.

Application

Electrical conductors

Cables

Switchgear

Power distribution

Copper T1

Electroplating (nickel, silver)

Annealing

Coating

Purity: High purity copper (minimum 99.85% Cu).

High conductivity, but slightly lower than TU0.

Improved strength compared to TU0, but still excellent ductility.

Wires

Cables

Heat exchangers

Radiators

Copper T2

Annealing

Electroplating (tin, nickel)

Coating

Purity: Slightly lower purity than T1, around 99.90% Cu.

Still very high, though slightly lower than T1.

Higher mechanical strength compared to TU0 and T1 but still maintains good ductility.

Electrical wires

Plumbing systems

Heat exchangers

Copper C10100

Electroplating (silver, tin)

Polishing

Lacquering

Purity: Oxygen-free copper (99.99% Cu).

Exceptional conductivity, high-performance electrical applications.

Excellent formability and ductility, with minimal risk of porosity or oxidation.

High-performance electrical components

Telecommunications

Aerospace

Copper C10200

Electroplating (tin, silver)

Polishing

Lacquering

Purity: Oxygen-free, high-conductivity copper (99.99% Cu).

Very high conductivity.

Excellent formability and ductility, highly resistant to oxidation.

High-conductivity cables

Vacuum systems

Cryogenics

Copper C11000

Electroplating (tin, nickel)

Polishing

Annealing

Purity: Copper with a purity of 99.90% Cu.

High conductivity, typically around 101-103% IACS.

Good ductility and strength.

Electrical wiring

Connectors

Bus bars