Industrial Equipment

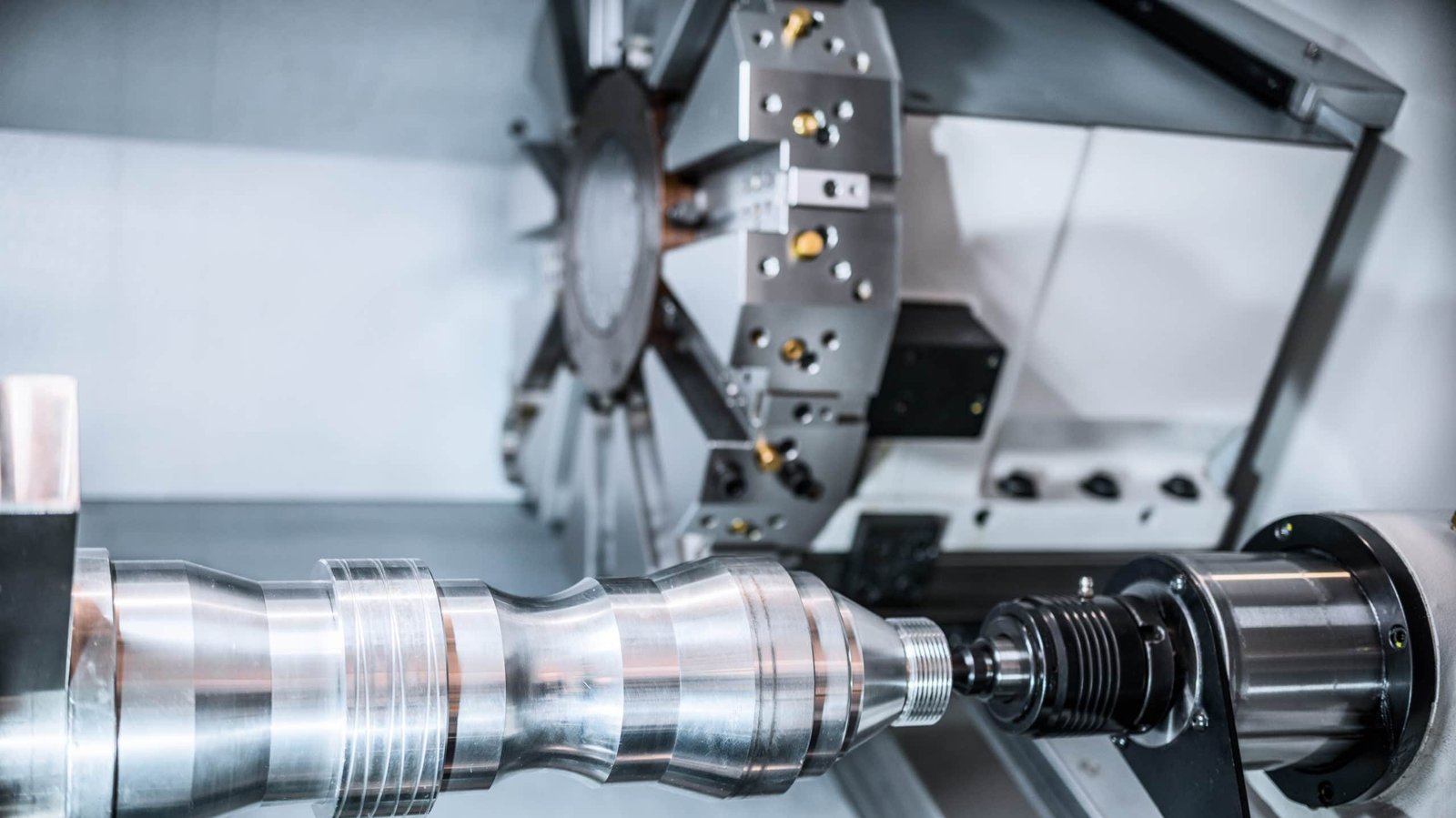

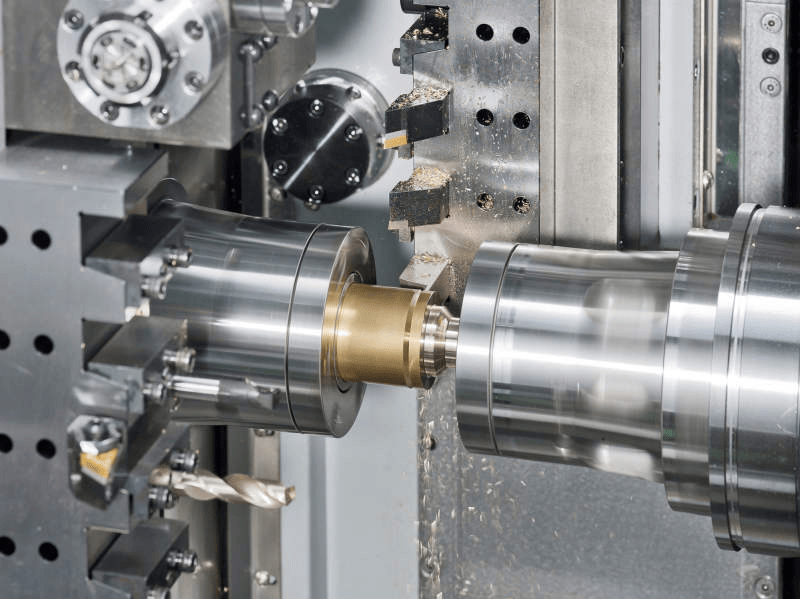

High-Precision CNC Machining for Industrial Equipment Parts

Custom machining solutions for heavy-duty machinery and industrial systems.

Reliable quality, fast delivery, global supply.

Advantages

Machining capabilities for large-sized and heavy-duty parts (up to 2m length, 3-ton weight)

Precision tolerance up to ±0.005mm for critical industrial components

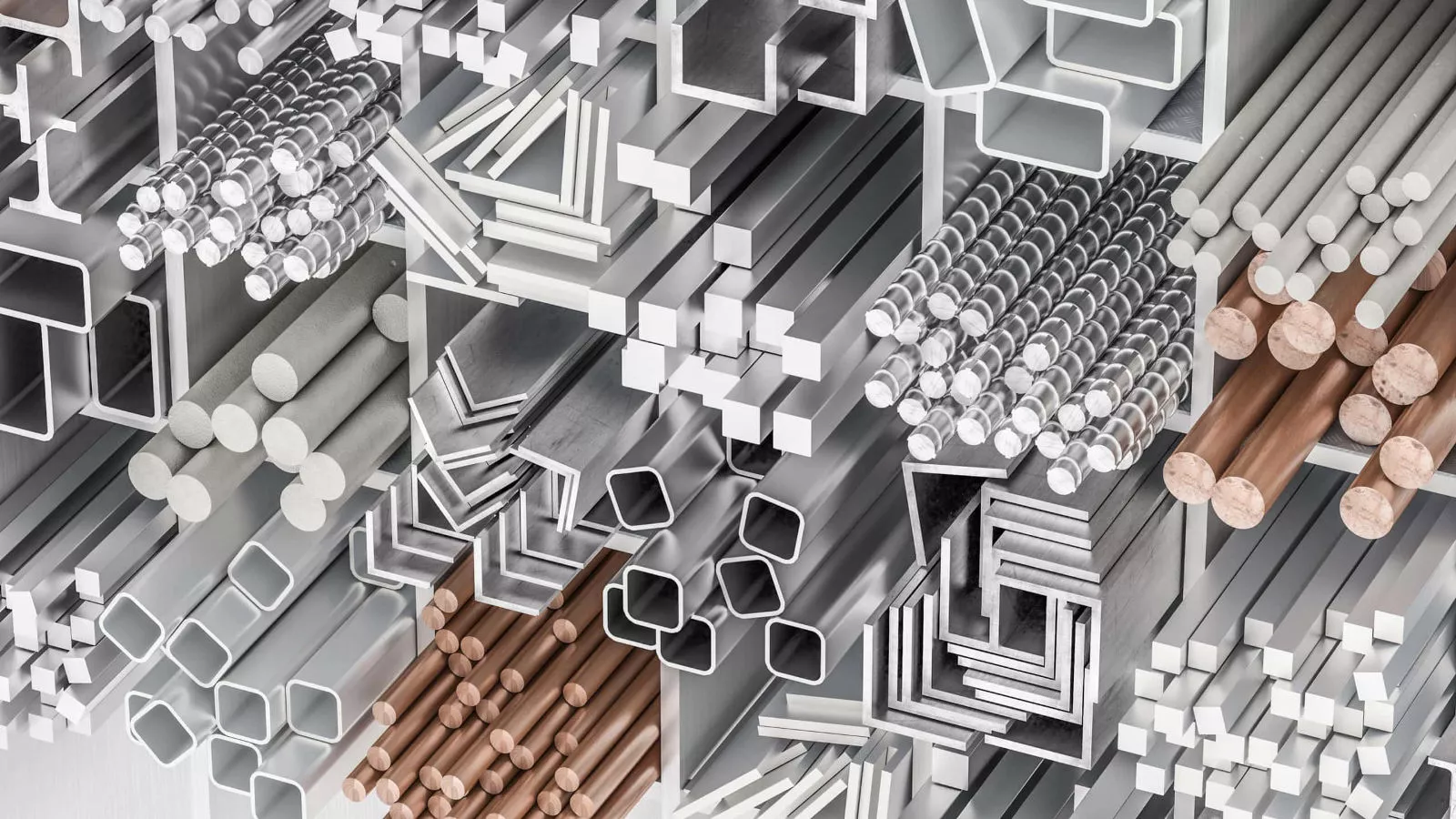

Wide material range: alloy steel, stainless steel, wear-resistant cast iron, engineering plastics

Full-service support: prototyping, small batch, and mass production

Strict quality inspection and international certification (ISO 9001 / IATF 16949)

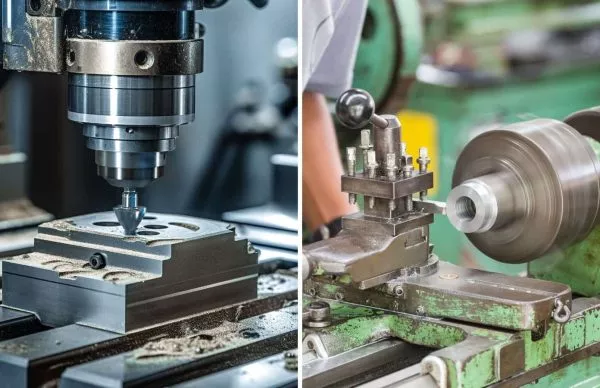

Why Choose CNC Machining Over Traditional Methods

When it comes to precision parts, cost is more than just the number on a quote — it’s about the value delivered. While traditional machining may offer lower upfront prices, it often involves higher labor costs, slower production speeds, and inconsistent accuracy.

CNC machining, on the other hand, provides tighter tolerances, faster turnaround, and minimal waste, which means fewer reworks and lower total costs in the long run. For complex, high-volume, or repeat projects, CNC delivers consistent quality at a competitive overall price, saving you both time and money.

Industries We Serve

Industry

GM-PRE CNC Advantages

Customer Value

Mining & Construction Machinery

Heavy-load CNC turning + wear-resistant coatings

Extend part lifespan, reduce downtime

Manufacturing Automation

Precision milling + high repeatability

Improve production efficiency

Energy & Power Equipment

Large-scale boring + heat-resistant materials

Enhance operational safety

Port & Transport Machinery

Corrosion protection + heavy-duty welding

Reduce maintenance cost

Other CNC Machining Capabilities

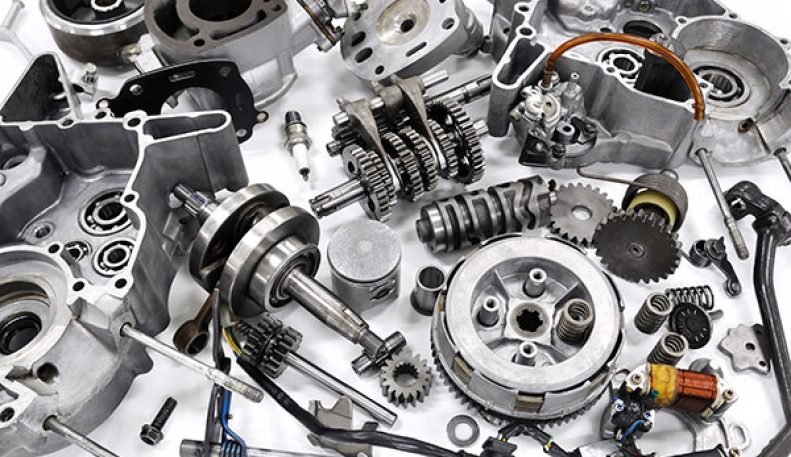

- Gear housings, shafts, coupling hubs

- Structural brackets, base plates

- Precision bushings, bearing housings

- Conveyor rollers, machine frames

5-axis CNC milling and high-precision turning

Large-part machining capacity (up to 2m length)

Advanced surface treatments: nitriding, anodizing, coating

Industrial Equipment Parts Applications

Manufacturing Automation

- Robot base plates,

- Linear guide supports

- Conveyor system components

Why Choose GM-PRE

Leverage our company’s advantages to help you better serve your customers

GuanMei PRE has long experience in manufacturing Industrial Equipment Parts.

Production Capacity

Industry Certifications including IATF16949Provide PPAP

Strict quality control

Provide professional quality inspection report √ Standard Inspection with Formal Report √ CMM Inspection with Formal Report √ Source Material Certification

Instant quote online

The online order page provides different parameters and processes to get a quote quickly