In the ever-evolving landscape of the automotive industry, precision, efficiency, and innovation are paramount. At the heart of this transformation lies CNC (Computer Numerical Control) machining, a technology that has redefined the manufacturing of automotive components. From crankshaft components and control arms to cylinder heads and brake components, CNC machining plays a pivotal role in crafting the intricate parts that power our vehicles.

Understanding CNC Machining

CNC machining is a manufacturing process that employs pre-programmed computer software to control machinery and tools. This technology can manipulate a variety of machinery, including lathes, mills, routers, and grinders, to create parts and components from raw materials like metal and plastic.

Key Components of CNC Machines

- Machine Tools: These include lathes, mills, and routers equipped with cutting elements that shape the material.

- Control Unit: Acts as the brain of the CNC machine, interpreting design files and translating them into machine instructions.

- Drive System: Manages the movement of machine tools along the x, y, and z axes.

- Feedback System: Utilizes sensors and feedback loops to ensure precise positioning, enhancing accuracy and repeatability.

Applications in the Automotive Industry

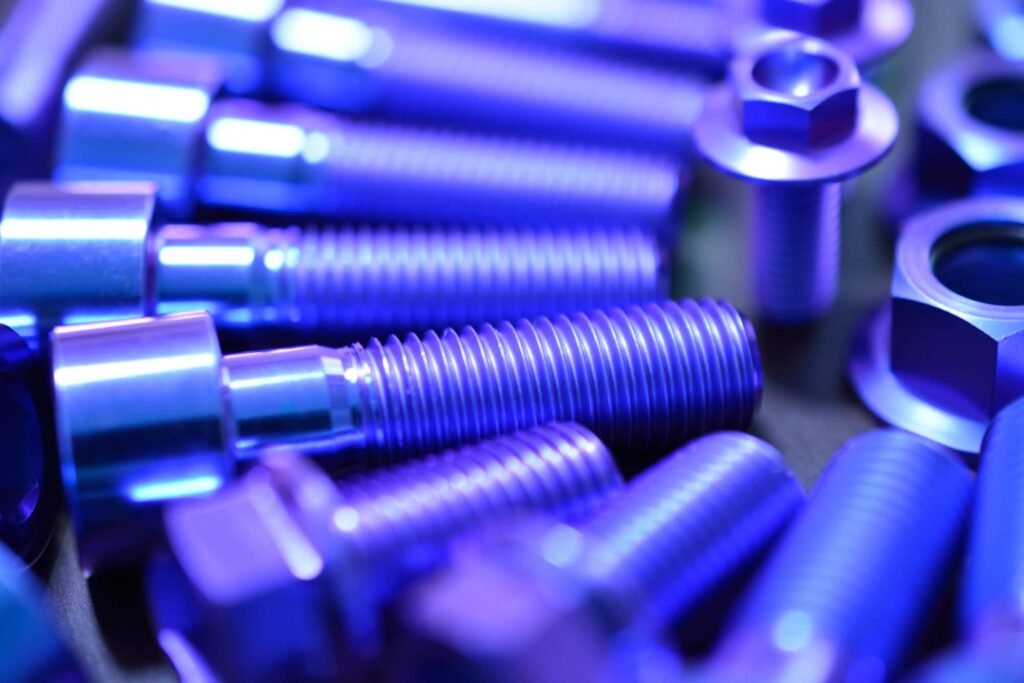

CNC machining’s precision and versatility make it ideal for manufacturing a wide array of automotive components:

Engine Components

- Cylinder Heads and Engine Blocks: CNC machining is crucial in creating these components with high accuracy, ensuring optimal engine performance and longevity.

- Crankshafts: Precision machining of crankshafts ensures smooth engine operation and durability.

Transmission Components

- Gears and Shafts: Machined to exact specifications to ensure efficient power transfer and smooth operation.

- Transmission Housings: Crafted with precision to maintain the integrity of the transmission system.

Brake Components

- Brake Rotors, Drums, and Calipers: CNC machining ensures these critical safety components meet high standards of precision and reliability.

Suspension Parts

- Control Arms and Shock Absorbers: Manufactured to provide consistent handling and stability.

Interior and Exterior Trim

- Dashboard Panels and Grille Inserts: CNC machining allows for detailed and aesthetically pleasing components that enhance vehicle design.

Benefits

CNC machining offers numerous advantages that make it indispensable for automotive manufacturing:

- Precision and Accuracy: Capable of producing parts with extremely tight tolerances, ensuring perfect fit and function.

- Repeatability: Once programmed, CNC machines can produce identical parts consistently, crucial for mass production.

- Efficiency: Capable of operating continuously with minimal supervision, increasing production rates and reducing labor costs.

- Flexibility: Easily reprogrammable to produce different parts, allowing manufacturers to adapt quickly to changes in demand or design.

- Quality Control: High precision and repeatability lead to superior quality parts, reducing the need for post-production inspection and rework.

Benefits

CNC machining offers numerous advantages that make it indispensable for automotive manufacturing:

- Precision and Accuracy: Capable of producing parts with extremely tight tolerances, ensuring perfect fit and function.

- Repeatability: Once programmed, CNC machines can produce identical parts consistently, crucial for mass production.

- Efficiency: Capable of operating continuously with minimal supervision, increasing production rates and reducing labor costs.

- Flexibility: Easily reprogrammable to produce different parts, allowing manufacturers to adapt quickly to changes in demand or design.

- Quality Control: High precision and repeatability lead to superior quality parts, reducing the need for post-production inspection and rework.

Future Trends

As technology advances, CNC machining is poised to play an even more significant role in The future of automotive manufacturing:

Integration with Additive Manufacturing: Combining CNC machining with 3D printing can optimize material usage and create complex parts previously impossible to manufacture.

Smart Manufacturing: The adoption of IoT and AI in CNC machining can enhance process monitoring, predictive maintenance, and overall efficiency.

Sustainability: Evolving CNC machining processes to become more energy-efficient and reduce waste aligns with the automotive industry’s push toward sustainability.

Advanced Materials: CNC machines will continue to evolve to handle the machining of advanced composites and alloys used in automotive applications.

Conclusion

Looking for a CNC Partner for Automotive Parts?

At Guanmei PRE Precision Metal Co., Ltd, we specialize in CNC milling, turning, and drilling for automotive components. Our ISO 9001-certified processes, multi-axis machining centers, and experienced engineering team ensure:

- Fast prototyping and sampling

- Medium-to-high volume production

- Full inspection and quality reports

- Global shipping and engineering support

Contact us today to discuss your automotive CNC part needs—or upload your drawing for a fast quote.

Key Automotive Components That Rely on CNC Machining

Everything You Need To Know About Anodizing