The Development of CNC Processing in the Production of Medical Devices

In today’s fast-changing industrial world, CNC (Computer Numerical Control) machining has become a game-changer—especially in making medical devices. Healthcare needs quick results, pinpoint accuracy, and reliable precision, and CNC machining delivers all that better than old-school manufacturing methods.

This article breaks down why CNC machining works better than traditional techniques, how medical devices rely on CNC processing, and why this tech is becoming a must-have in the industry.

How CNC Machining Fits Into Medical Device

CNC machining uses computer-controlled machines to turn raw materials like wood, plastic, and metal into detailed, super-precise parts. In healthcare, where getting things exactly right can make or break a device’s safety and effectiveness, this tech is indispensable. Whether it’s prosthetics or surgical tools, CNC machining ensures parts meet the strictest industry standards.

How CNC Makes Medical Devices

Making medical devices with CNC machining involves a few key steps:

- Designing the Plan: It all starts with a computer-aided design (CAD) of the device, which gets turned into a digital file.

- Setting Up the Machine: The CNC machine reads that CAD file, interprets the design, and creates a 3D model to follow.

- Shaping the Material: Using tools like drills, mills, and lathes, the machine cuts and shapes the raw material into the exact shape needed.

- Checking Quality: Thanks to its automated setup, CNC machining keeps quality and accuracy consistent—something that’s critical for medical tools and devices.

Why CNC Beats Traditional Manufacturing for Medical Devices

CNC machining is a top pick for making medical devices because it offers big advantages over old manufacturing methods.

- Accuracy That Matters

In healthcare, getting things precisely right is non-negotiable. CNC machines hit levels of accuracy no other method can match—vital for complex medical gear where even tiny mistakes could cause serious problems.

- Scalability and Consistency

Need to make lots of identical parts? CNC machining handles big batches without sacrificing quality. Every piece comes out the same, which is a huge plus for medical production.

- Material Versatility

Medical devices require diverse materials, from titanium to thermoplastics. CNC machining can handle a wide range of materials, providing flexibility in design and application。

Real-World Applications of CNC Machining in Healthcare

CNC machining’s versatility is evident in various medical applications:

- Surgical Instruments: Precision tools like scalpels and forceps are crafted to exact specifications.

- Implants and Prosthetics: Customized implants provide better fit and function for patients.

- Diagnostic Equipment: CNC-machined components ensure reliability and accuracy in diagnostic tools.

- Dental Devices: From crowns to bridges, CNC machining ensures perfect fit and durability.

Challenges and Considerations in CNC Machining for Healthcare

While CNC machining offers numerous benefits, manufacturers must navigate challenges such as:

- Regulatory Compliance: Ensuring products meet health and safety standards.

- Material Biocompatibility: Selecting materials safe for human use.

- Quality Control: Implementing rigorous checks to maintain high standards.

In summary

CNC machining has revolutionized the way medical devices are manufactured. Compared to old processes, it is far more efficient, precise, and allows for more personalization. Additionally, as the healthcare industry continues to undergo further transition, the significance of computer numerical control (CNC) machining in shaping the industry’s future is only going to increase. To be competitive, firms must include this technology in their products. Because trustworthy and accurate medical equipment is in demand. Check out our materials and talk to industry experts to learn how computer numerical control (CNC) machining may enhance your production processes and healthcare. If you have this tendency to apply this technology to your medical device, you can contact us without thinking twice!

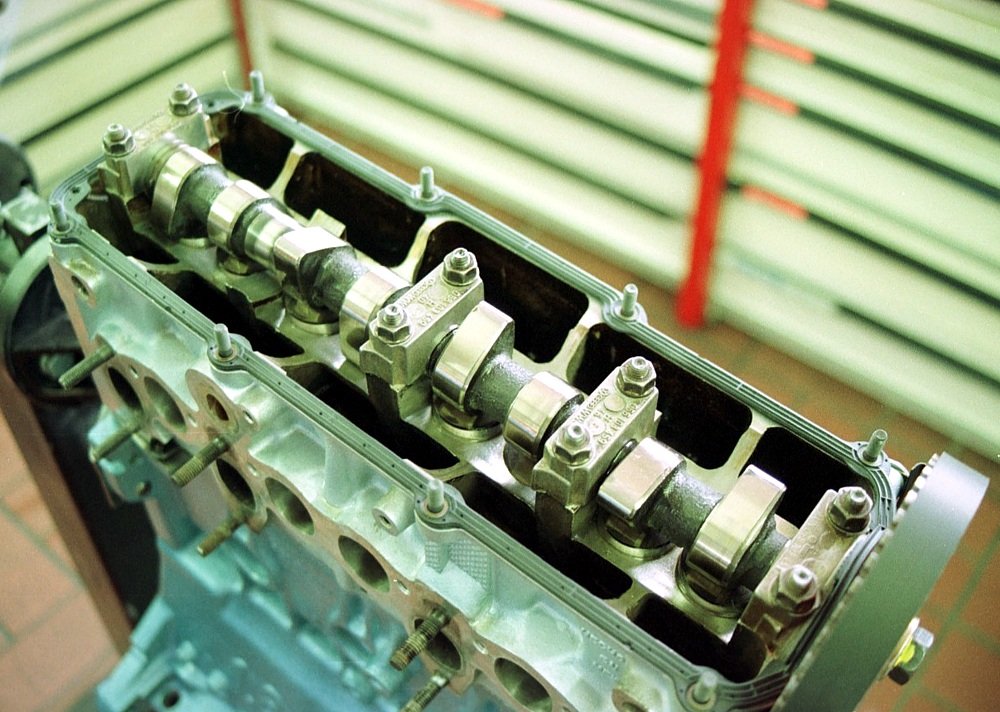

CNC in Camshaft Manufacturing